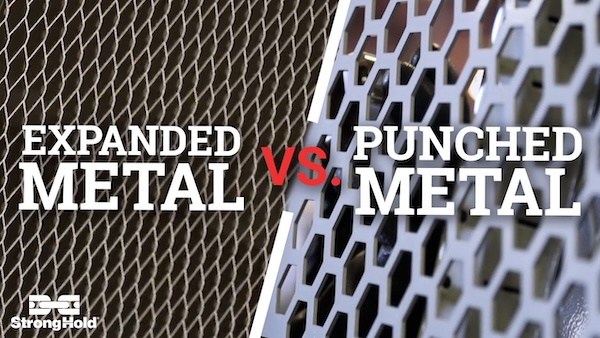

Punched Metal vs. Expanded Metal: Why Strength and Security Matter in Ventilated Cabinets

When it comes to ventilated industrial storage cabinets, construction makes all the difference. When considering a ventilated storage solution, consider how the vents are cut into the material. Two of the most common options are expanded metal and punched metal, but the performance between the two couldn’t be further apart. At Strong Hold, we’ve tested both side by side, and the results clearly show that punched metal is the superior choice for strength, durability, and security.

What Is Expanded Metal?

Expanded metal begins as a sheet of steel that’s cut and stretched into a diamond-shaped pattern. The process allows manufacturers to cover a large surface area with less material.

- Advantage: Cost-effective and lightweight.

- Disadvantage: Stretching the sheet compromises its structural integrity, making it less flexible, weaker, and more prone to bending under stress.

While expanded metal may look sturdy, the “shake, rattle, and roll” test quickly shows its limitations: it’s noisy, unstable, and lacks rigidity.

What Is Punched Metal?

Punched metal starts with a solid sheet of steel and uses a high-tonnage press to punch consistent ventilation holes. Unlike expanded metal, the sheet’s structural integrity is preserved.

- Advantage: Maintains the strength of the base steel.

- Advantage: Resistant to bending, cutting, and tampering.

- Advantage: Provides reliable ventilation without sacrificing durability.

In Strong Hold’s cabinets, punched metal panels remain sturdy, quiet, and secure, even under heavy use.

Security: A Critical Difference

If you’re locking up valuable tools, equipment, or gear, expanded metal poses a serious vulnerability. Standard wire cutters can easily cut through it in a matter of seconds.

Punched metal, on the other hand, can withstand the same test with barely a scratch. The heavy-gauge steel is nearly impossible to cut with hand tools, providing the peace of mind you need when securing high-value assets.

Durability That Lasts

Expanded metal may be lightweight, but that also means it bends and warps easily over time. By contrast, punched metal remains a solid, structural component, able to handle years, even decades, of daily abuse in industrial environments.

This is why Strong Hold exclusively uses punched steel for our ventilated cabinets. Available in both diamond and hex punch patterns. It’s not just about airflow; it’s about building a product that lives up to our promise: Built to Outlast Everything.

Choosing the Right Cabinet Material

When deciding between expanded metal and punched metal, consider what matters most for your operation:

- Strength: Will the cabinet withstand heavy use?

- Security: Will your gear stay protected from tampering or theft?

- Longevity: Will the panels bend and break, or remain solid for years?

For Strong Hold, the answer is clear: punched metal delivers unmatched strength, security, and reliability.

Expanded metal may be cheaper upfront, but it comes at the cost of durability and peace of mind. Punched metal offers the best of both worlds, ventilated storage without compromising security or strength.

That’s why Strong Hold builds every ventilated cabinet with all-welded, punched-steel construction. When you choose punched metal, you’re choosing a cabinet that’s engineered for abuse, made in the USA, and backed by up to a 99-year warranty.

Interested in ventilated storage solutions? Don’t settle for expanded metal; get the durability you deserve with punched steel.

Shop ventilated cabinets online today or contact your preferred Strong Hold dealer.