Flammable Safety Cabinets: Protect Your People, Property, and Compliance

In any industrial setting where flammable or combustible liquids are used, safety isn’t optional; it’s mandatory. Whether you’re running an automotive shop, manufacturing plant, maintenance facility, or research lab, storing these materials properly is critical to protecting your team, your equipment, and your entire operation.

That’s where flammable safety cabinets come in.

These heavy-duty storage solutions are purpose-built to reduce fire risk, organize hazardous materials, and keep your facility compliant with key safety standards, including OSHA 29 CFR 1910.106, which governs the storage of flammable and combustible liquids, and NFPA 30: Flammable and Combustible Liquids Code, which outlines proper design and storage practices to minimize fire hazards.

In this article, we’ll break down what flammable safety cabinets are, what key features to look for, why they’re essential, regulatory requirements, and how Strong Hold flammable safety cabinets protect your workspace. Because when it comes to fire safety, cutting corners isn’t just dangerous, it’s costly.

What Is a Flammable Safety Cabinet?

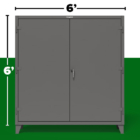

The Strong Hold 30.5PSC flammable safety cabinet

A flammable safety cabinet is a specialized, fire-resistant storage unit designed to safely house flammable or combustible liquids and chemicals.

Its primary purpose is to reduce the risk of fire, contain hazardous vapors, and provide workers with safe, organized access to volatile substances.

These cabinets are built to regulatory standards and act as a first line of defense against workplace fires. In the event of a blaze, a properly constructed flammable safety cabinet helps delay ignition of its contents, giving personnel time to respond and emergency systems time to activate.

Key Features to Look for in a Flammable Safety Cabinet

Not all flammable safety cabinets are built the same, and when you’re storing flammables, the details matter. Whether you’re outfitting a new facility or upgrading outdated equipment, here are the essential features you should look for from any flammable safety cabinet:

Double-Walled, All-Welded Steel Construction

A high-quality flammable safety cabinet should be built from heavy-gauge steel with dual walls and at least 1.5 inches of insulating air space. This design slows heat transfer during a fire, giving you valuable time to respond and contain the situation. All Strong Hold flammable safety cabinets are constructed from 12 or 14-gauge steel.

Self-Closing or Manual Doors

Doors should latch securely and close automatically or manually, depending on your local codes. Self-closing models utilize a fusible link that triggers door closure when exposed to high heat, which is particularly critical in fast-moving fire events. Strong Hold offers flammable safety cabinets with either self-closing or manual doors.

Spill Containment Sump

Look for a leakproof sump at the cabinet base. It’s designed to capture spills or leaks from damaged containers, keeping flammable liquids off your floors and out of your workspace. Each Strong Hold flammable safety cabinet includes a spill containment sump.

Adjustable Shelves

Chemical containers come in all shapes and sizes. Adjustable shelves give you flexibility while helping prevent over-stacking or unsafe storage practices. Each Strong Hold flammable safety cabinet includes adjustable shelves.

Grounding Connections

For flammable liquids prone to static discharge, grounding connections are a must. Proper grounding helps dissipate static electricity safely, reducing ignition risk during container transfer or handling. Each Strong Hold flammable safety cabinet includes grounding connections.

Clear Hazard Labeling

All flammable cabinets should be clearly labeled with bold, durable signage; usually “Flammable – Keep Fire Away.” This isn’t just best practice; it’s required under OSHA and NFPA codes.

Locking Mechanisms

Security is part of safety. A locking handle or padlock hasp ensures that only authorized personnel can access the contents—protecting both people and property.

Color Coding

OSHA recommends yellow for flammable liquid storage, but color-coding goes further: red for combustible materials, blue for corrosives, green for non-hazardous, and so on. It’s an easy way to boost organization and avoid dangerous mix-ups.

Flammable Safety Cabinets Regulatory Requirements:

When it comes to flammable storage, it’s not just about doing the right thing; it’s about meeting strict federal, state, and local regulations. Failure to comply can result in steep fines, failed inspections, or even facility shutdowns. Strong Hold flammable safety cabinets are engineered to meet these critical safety standards:

OSHA 29 CFR 1910.106

This regulation from the Occupational Safety and Health Administration governs the safe storage of flammable and combustible liquids in the workplace. It outlines:

- Maximum quantities allowed outside of approved storage cabinets

- Requirements for cabinet construction and labeling

- Safe placement and usage guidelines

Key takeaway: If your facility stores more than 25 gallons of Class I flammable liquids outside of a compliant cabinet, you’re at risk of noncompliance.

NFPA 30 – Flammable and Combustible Liquids Code

Developed by the National Fire Protection Association, NFPA 30 is the gold standard for fire protection when handling flammable liquids. It provides detailed guidance on:

- Cabinet ventilation (or lack thereof)

- Material and construction specs

- Storage limits per area and cabinet

- Separation of incompatible chemicals

Key takeaway: NFPA 30 helps you go beyond the minimum and adopt best practices that reduce fire hazards and protect personnel.

FM Approved

Third-party certifications like FM Global (Factory Mutual) confirm that a cabinet has been independently tested for fire resistance and structural integrity under extreme conditions.

Key takeaway: FM-listed cabinets provide an added level of confidence and may even be required by your local fire marshal or insurance provider.

Why You Need a Flammable Safety Cabinet

If your facility stores or uses flammable liquids, a flammable safety cabinet isn’t just a nice-to-have; it’s a must-have. These cabinets play a critical role in protecting your team, your property, and your bottom line.

Fire Risk Reduction

Flammable safety cabinets are designed to contain volatile substances and isolate them from ignition sources like sparks, heat, or open flame. In the event of a fire, the cabinet helps delay flashover and gives emergency responders valuable time to act. It’s a frontline defense that can mean the difference between a close call and a catastrophe.

Employee Safety

Exposure to flammable chemicals can lead to dangerous vapors, skin contact, or inhalation hazards. A properly sealed and labeled cabinet minimizes these risks, keeping harmful chemicals contained and ensuring workers can safely access materials without putting themselves in harm’s way.

Regulatory Compliance

As previously mentioned, agencies like OSHA and the EPA mandate specific storage requirements for flammable liquids. Failing to comply with such standards can result in hefty fines, operational shutdowns, or worse. Flammable safety cabinets help your business meet these requirements and pass safety audits with confidence.

Organization & Inventory Management

Flammable cabinets don’t just improve safety; they help streamline your operation. With designated shelving, clear hazard labeling, and compliant container storage, your team can find what they need faster and avoid costly mix-ups or misplacements.

Strong Hold’s Flammable Safety Cabinet Solution

When it comes to flammable safety storage, you don’t need a cabinet that looks compliant; you need one that actually is. At Strong Hold, we build fire-resistant cabinets that check every box and crush the competition on durability, security, and American-made quality.

Here’s what sets ours apart:

- All-Welded Steel Construction: Available in 12- or 14-gauge steel; no rivets, no bolt-together nonsense.

- Built to Code: Every unit meets or exceeds OSHA 29 CFR 1910.106 and NFPA 30 requirements.

- Made in the USA: Engineered and manufactured right here in the States.

These aren’t just safety cabinets. They’re Strong Hold cabinets, built tough to keep your crew, your assets, and your facility protected when it matters most.

Ready to upgrade your flammable safety storage?

Shop Flammable Safety Cabinets or Request a Custom Quote, and we’ll build a solution that’s fire-ready and field-proven.