Heavy Duty Industrial Storage Solutions for Sonoco’s Metal Stamping Facility

Uncompromising Protection in a Demanding Metal Stamping Environment

Overview

Sonoco, a global leader in consumer packaging solutions, operates a metal stamping facility in Memphis, Tennessee, where precision, safety, and durability are essential. When storing, transporting, and working with heavy dies, tools, and components, Sonoco needed heavy-duty industrial storage solutions and workspaces that could handle the extreme demands of their operation. To achieve this, they turned to Strong Hold and its dealer network for industrial-grade, custom-engineered solutions built to last.

Challenge

Sonoco’s Memphis facility processes steel coils weighing over 20,000 lbs, stamping out packaging parts for some of the largest food and consumer goods companies in the world. The facility’s die and tool makers previously relied on carts, benches, and storage units fabricated in-house over the years—some dating back to the 1970s. These makeshift solutions had begun to deteriorate, creating safety risks and workflow inefficiencies.

Key challenges included:

- Replacing outdated, piecemeal equipment with heavy-duty industrial storage solutions that offer durable, high-capacity performance

- Providing safe, maneuverable carts for transporting heavy tooling around the plant

- Adding organized, secure storage for tools and components

- Improving ergonomics and employee workspace satisfaction

- Reducing the need for employees to fabricate their own storage solutions

Solution

Maintenance Manager Bobby Benedetti, already familiar with Strong Hold’s quality from a previous employer, partnered with Strong Hold’s engineering team to design custom heavy duty industrial storage solutions that met Sonoco’s exact needs.

The Strong Hold package included:

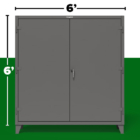

- 66-PB-244 Sixty Six Series Cabinet – Extreme Duty 12-gauge cabinet with pegboard doors, four adjustable shelves, and all-welded construction for secure and organized tool storage.

- Extreme Duty 7-Gauge Shop Table – Equipped with three drawers, a maple top for precision work, and a custom pegboard for additional vertical tool organization.

- Extreme Duty 12-Gauge Mobile Service Cart – Featuring a 12-gauge steel top, two shelves, 6” heavy-duty casters for mobility, and a removable 2” guard chained to the cart for securing loads.

Results

The upgrade provided Sonoco with immediate operational benefits:

- Safety – Strong, stable equipment reduced the risk of accidents and improved handling of heavy materials.

- Durability – Heavy-duty construction eliminated concerns about collapsing shelves or deteriorating work surfaces.

- Efficiency – Custom mobility solutions made moving heavy tools safer and faster.

- Employee Satisfaction – Improved ergonomics, 5S organization, and secure personal storage enhanced workplace comfort and productivity.

- Cost Savings – No more time or resources spent fabricating in-house equipment that couldn’t meet the same performance standards.

Bobby summarized it simply:

“Buy it one time and you’ll never have to buy it again. That’s key for me.”

Key Takeaways

Strong Hold’s engineering expertise, combined with Sonoco’s operational requirements, delivered purpose-built solutions that elevated safety, organization, and efficiency in a demanding industrial environment.

Conclusion

When uncompromising protection is essential, Strong Hold delivers. For Sonoco, investing in extreme-duty storage and workspace equipment has provided long-term reliability and peace of mind.

If your facility is in need of custom heavy-duty industrial storage solutions, contact us using our custom quote form to get our team started on your project!